6-20 個字符(僅限字母加數字)

密碼不一致

EFU(設備風扇過濾器單元)設備側空氣過濾

在Deshengxin,我們了解精確空氣過濾對高性能設備的至關重要性。這就是為什麼我們開發了最先進的設備風扇濾清器單元(EFUS),該單元(EFUS)專門旨在在使用時直接提供優化的空氣質量,從而保護精緻的過程並最大程度地提高生產率。 DeShengxin的EFU用於設備側用途的核心特徵:1。精確過濾:我們的EFU的核心在於其高級過濾器,能夠從空氣流中捕獲和去除微小的顆粒和污染物。通過濾波器選項,從MERV(最低效率報告值)等級到HEPA和ULPA等級,我們可以根據您的特定要求來定制EFU,以確保最大的過濾效率。 2。智能氣流管理:EFU內的內置風扇旨在最佳氣流管理,可精確控制所提供給設備的空氣的數量和方向。這有助於創建一個對精確工作和敏感操作必不可少的局部,無污染物的環境。 3。簡單集成:DeShengxin的EFU旨在無縫集成到您現有的設備或系統中。緊湊,輕巧且具有模塊化連接,我們的EFU可以快速安裝,而對您的生產計劃的中斷最小。 4。可靠的操作:每個EFU均採用高質量的組件進行設計,並進行嚴格的測試,以確保長期可靠性和無故障操作。通過過熱的保護,降噪措施和先進的運動技術,您可以相信我們的EFU在苛刻的條件下提供一致的性能。 5。維護友好的設計:我們的EFUS功能可訪問的過濾室,簡化了例行維護任務,例如更換過濾器。借助易於遵循的說明和真正的更換零件的可用性,維護非常快,直接,並確保設備的最大正常運行時間。 6.能源效率:配備節能風扇和電動技術,Deshengxin的EFU旨在最大程度地減少能源消耗而不損害過濾性能。這不僅降低了您的運營成本,而且還與對環境負責的做法保持一致。 7.多功能和可定制:認識到每個應用程序都是唯一的,我們提供的EFU可以自定義以滿足特定的尺寸,重量和氣流要求。無論您是需要標準配置還是定制的解決方案,Deshengxin的專家團隊都將與您緊密合作,以開發滿足您需求的完美EFU。應用: - 工業機器和自動化系統的外殼通風- 電子製造和組裝的局部清潔空氣供應- 半導體晶圓處理和測試的關鍵點過濾- 實驗室設備和儀器的保護性通風- 藥物和生物技術環境的清潔室設備通風: Deshengxin的設備側空氣過濾的EFU代表了確保直接將高質量空氣傳遞到最關鍵的設備的理想解決方案。通過精確過濾,智能氣流管理,可靠的操作和多功能性,我們的EFU將幫助您最大程度地提高生產效率並保護敏感過程免受污染。立即與我們聯繫,以了解有關我們的EFU如何改變設備的空氣處理功能的更多信息。

Deshengxin's Equipment Fan Filter Units (EFUs) are advanced air filtration systems designed to provide clean, contaminant-free air directly to critical equipment. These units are an essential component in maintaining optimal working conditions for processes that require high air quality, such as electronics manufacturing, pharmaceutical production, and laboratory research.

Key Features & Benefits:

1. Advanced Filtration Technology:

Our EFUs employ state-of-the-art filters, available in various grades from MERV to HEPA and ULPA. These filters effectively remove airborne particles, dust, smoke, bacteria, and other contaminants, ensuring that only clean air reaches your equipment.

The filter media is chosen based on your specific needs, ensuring maximum filtration efficiency without undue pressure drop.

2. Intelligent Airflow Control:

The integrated fan within the EFU is engineered to deliver precise airflow control, tailored to the specific requirements of your equipment. This ensures a consistent and uniform supply of clean air, enhancing the overall performance and reliability of your processes.

Adjustable fan speeds and airflow patterns allow for fine-tuning to match your exact ventilation requirements.

3. Compact & Modular Design:

Deshengxin's EFUs feature a compact, modular design that is easy to integrate into existing equipment or production lines. This not only saves space but also simplifies installation and maintenance procedures.

The units are constructed from durable materials that resist corrosion and wear, ensuring long-term durability and reliability.

4. Low Noise Operation:

Special attention has been paid to noise reduction in the design of our EFUs. The fans and motors are equipped with sound-dampening features, ensuring quiet operation that does not interfere with your work environment.

5. Energy Efficiency:

Energy-saving fan motors and optimized airflow design contribute to reduced power consumption, lowering your operational costs.

Deshengxin's EFUs are designed to minimize energy waste, aligning with your sustainability goals.

6. Easy Maintenance:

The filter compartments are easily accessible, allowing for quick and simple filter replacements. This minimizes downtime and ensures continuous operation of your equipment.

Maintenance instructions and replacement parts are readily available, making self-maintenance straightforward.

7. Customization Options:

We recognize that every application is unique. That's why we offer EFUs that can be customized to meet specific size, weight, and airflow requirements. Our expert team will work closely with you to design and manufacture a custom EFU that perfectly suits your needs.

8. Reliable Performance:

Each EFU undergoes rigorous testing during the manufacturing process to ensure reliability and longevity. Overheat protection, motor safeguards, and other safety features ensure trouble-free operation under demanding conditions.

Applications:

Ventilation of enclosures and cabinets for industrial automation and machinery

Cleanroom environments in pharmaceutical, biotechnology, and medical device manufacturing

Electronics assembly lines, where contamination-free air is crucial

Semiconductor wafer handling and processing, requiring ultra-clean conditions

Laboratory research and instrumentation, ensuring accurate results

Conclusion:

Deshengxin's EFUs are the ultimate solution for ensuring clean, high-quality air is delivered directly to your critical equipment. With advanced filtration technology, intelligent airflow control, a compact modular design, and energy-efficient operation, our EFUs are designed to enhance the performance and reliability of your processes. Contact us today to learn more about how our EFUs can benefit your operation and elevate your air filtration standards.

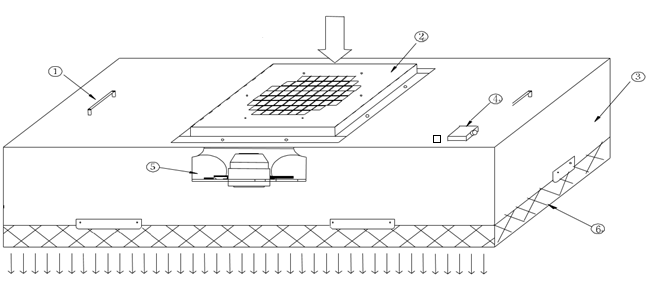

FFU Assembly diagram

|

1 |

|

5 |

Motor |

|

2 |

|

6 |

HEPA filter |

|

3 |

|

|

|

|

4 |

|

|

|

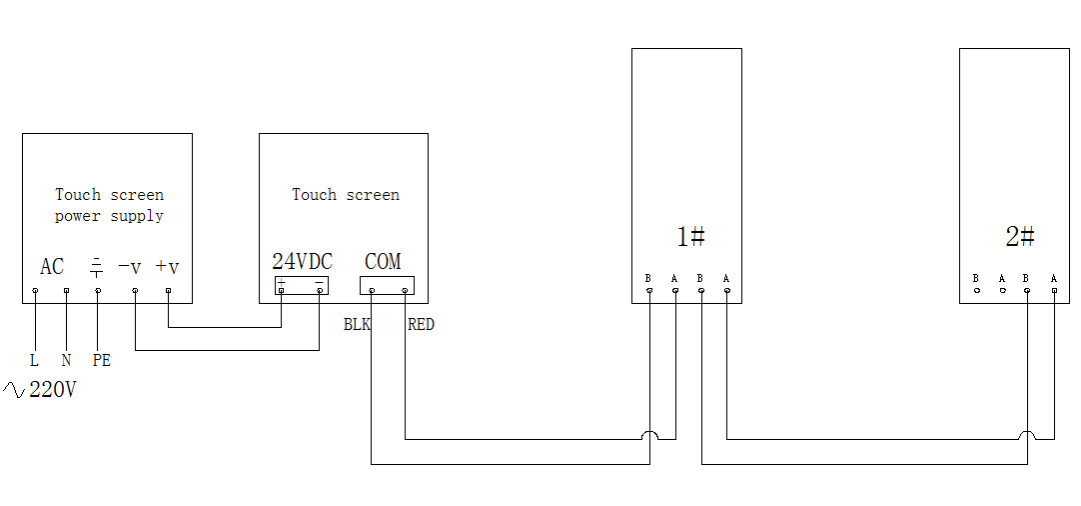

FFU Wiring diagram (Group control)

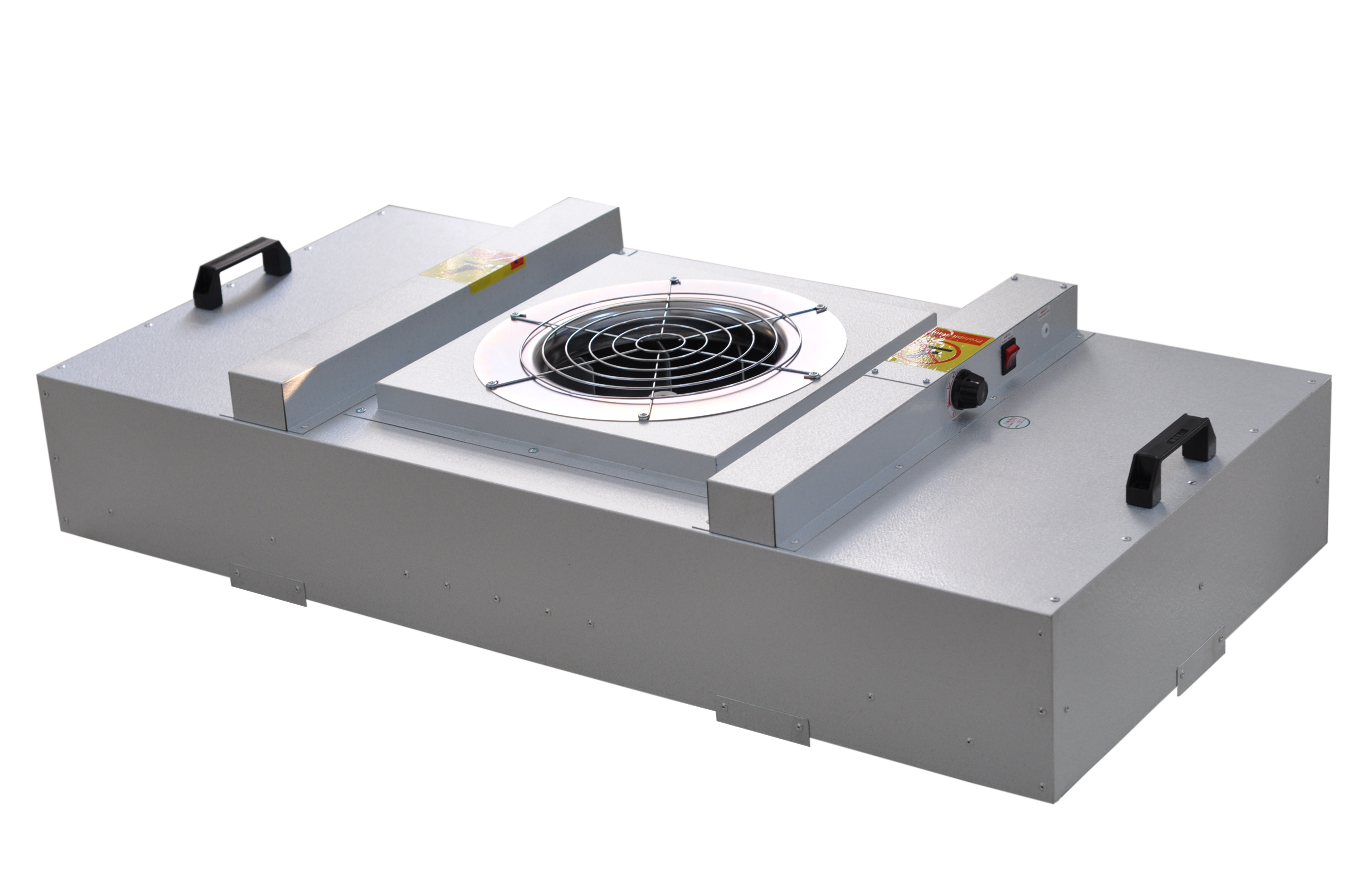

DSX FFU Introduction

Versatile FFU Systems with Customizable Materials, Motors, and Controls

Materials for ontology that can be used as an option such as steel plate paint stainless steel 304, 316 Aluminum plate Optional several efficient AC/DC motors

Individually controlled and centrally via a computer network. It can also be monitored remotely

Filters are made from fiberglass, PTFE, or are available using HEPA, ULPA filters of various levels of filtration.

Effective and quiet FFU Systems that are Space-Saving Design and a Stable Airflow.

DSX FFU uses an easy and light design which saves space and facilitates installation and maintenance.The particular design of the air intake and air conduit layout reduces noise, vibration, and noise production.

The internal diffuser plate provides an even air pressure distribution and stability of wind speed at the outlet.

Customizable FFU Systems with Energy-Efficient Motors

It is powered by a high-efficiency motor that can be adjusted to three speeds and low power consumption and low operating expenses (DC motors are also chosen to save energy). The motor was developed and manufactured by DSX and is able to be adjusted in accordance with the needs of the customer.

Versatile FFU Systems with Multiple Filter Options for Superior Filtration

Filter materials could be fiberglass, PTFE or optional HEPA and ULPA filtering systems with various filtering levels. Filter grade options include H13, U14 U15 and U16.

Perfect for special events

In addition to FFUs that are used in normal situations, we also offer FFUs that are specifically designed for industries that use lithium batteries, extremely thin FFUs for spaces with limited space, and explosion-proof FFUs. As a leading FFU producer, we are able to customize FFUs to suit various situations for our customers.

Make sure you are in a clean area

Each of DSX FFUs is assembled in cleanrooms to guarantee an extremely clean environment. Our FFUs strictly follow the strictest guidelines and adhere to cleanroom procedures throughout the production process. This strict approach ensures we can guarantee that the FFUs are clean of any contamination, which is essential to ensure optimal performance while maintaining clean working environments across a variety of applications.

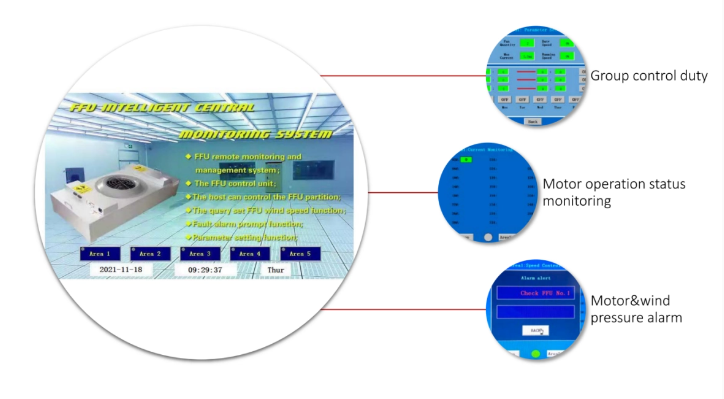

Customizable FFU Control System: Enhancing Efficiency and Performance

We have developed our FFU control system was developed and created by our own engineers, offering unparalleled flexibility and customization. With attention to particulars the control system we use offers an array of customizable options to satisfy specific customer needs. If it's creating the interface for control, altering rates of baud, or choosing the preferred option for display language Our control system is able to be customized to meet different communication styles and requirements of the customer. This flexibility allows for an easy integration into existing systems, and increases the overall effectiveness and efficiency for our FFUs.

Deshengxin FFU Regular parameters

| DESCRIPTION | Size(L*W*HMM) (Including HEPA) |

Air velocity (m3/h) |

Air flow (m/s) | Noise | Position of testing noise | Shell material | Power Supply | Rated power |

| Ultra thin FFU | 1175*575*180 | 1000 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.17kw |

| FFU575575 | 575*575*320 | 500 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.12kw |

| FFU615615 | 615*615*320 | 700 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.12kw |

| FFU915615 | 915*615*320 | 900 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.12kw |

| FFU1175575 | 1175*575*320 | 1000 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.12kw |

| FFU1175*1175 | 1175*1175*350 | 2000 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.18kw |

The size and other parameters can be customized according to the clients' demands.

Partial custom parameters are as follows.

1.FFU parameters(CE):

|

Model |

DSX-FFU01-02 |

DSX-FFU01-02 |

DSX-FFU01-03 |

DSX-FFU02-02 |

DSX-FFU02-04 |

|

FFU dimension (mm) |

575 x 575 x 210 |

1175 x 575 x 210 |

1175 x 575 x 270 |

1175 x 1175 x 270 |

1175x1175x210 |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

||||

|

Fan |

AC |

||||

|

Input |

230ACV/60HZ/1P |

||||

|

Speed (m/s) |

0.45~1 m/s±20% at high speed |

||||

|

Control type |

Manual |

||||

|

HEPA Height (mm) |

50 / 70 Optional |

||||

|

HEPA filter material |

Glass fibre |

||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||

|

Operating temperature |

10~40℃ |

||||

|

Structure type |

Split type |

||||

|

Installation mode |

Horizontal / Vertical |

||||

2. FFU parameters(Ultrathin type):

|

Model |

Ultrathin type |

|||

|

FFU dimension (mm) |

875X575X160 |

1350X460X160 |

1600X460X160 |

Other dimension |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

|||

|

Fan |

AC / EC |

|||

|

Input |

220ACV/50HZ/1P |

|||

|

Speed (m/s) |

0.45~0.7 m/s±20% at high speed |

|||

|

Control type |

Manual / RS485 |

|||

|

HEPA Height (mm) |

50 / 70 Optional |

|||

|

HEPA filter material |

Glass fibre |

|||

|

HEPA efficiency |

H13 / H14 /U15 |

|||

|

Operating temperature |

10~40℃ |

|||

|

Structure type |

Split type |

|||

|

Installation mode |

Horizontal / Vertical |

|||

3.FFU parameters(Conventional type):

|

Model |

Conventional type |

||||

|

FFU dimension (mm) |

575x575x230 |

765X510X230 |

1000X520X230 |

1175X575X230 |

Other |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

||||

|

Fan |

AC / EC |

||||

|

Input |

220ACV/50HZ/1P |

||||

|

Speed (m/s) |

0.45m/s±20% at high speed |

||||

|

Control type |

Manual / RS485 |

||||

|

HEPA Height (mm) |

50 / 70 Optional |

||||

|

HEPA filter material |

Glass fibre |

||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||

|

Operating temperature |

10~40℃ |

||||

|

Structure type |

Split type |

||||

|

Installation mode |

Horizontal / Vertical |

||||

4.FFU parameters(High speed type ):

|

Model |

High speed type |

|||

|

FFU dimension (mm) |

430X430X270 |

1175X575X270 |

1175X175X270 |

Other |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

|||

|

Fan |

AC / EC |

|||

|

Input |

220ACV/50HZ/1P |

|||

|

Speed (m/s) |

1m/s±20% at high speed |

|||

|

Control type |

Manual / RS485 |

|||

|

HEPA Height (mm) |

50 / 70 Optional |

|||

|

HEPA filter material |

Glass fibre |

|||

|

HEPA efficiency |

H13 / H14 /U15 |

|||

|

Operating temperature |

10~40℃ |

|||

|

Structure type |

Split type |

|||

|

Installation mode |

Horizontal / Vertical |

|||

5.FFU parameters(Special type ):

|

Model |

F-DA190X1-SUS304-400X400X100-F50H13 |

F-DA190X1-SUS304-430X430X120-F70H13 |

|

FFU dimension (mm) |

400 X 400 X 100 |

400 X 400 X 120 |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

|

|

Fan |

AC |

|

|

Input |

220ACV/50HZ/1P |

|

|

Speed (m/s) |

0.25m/s±20% at high speed |

|

|

Control type |

Manual |

|

|

HEPA Height (mm) |

50 / 70 Optional |

|

|

HEPA filter material |

Glass fibre |

|

|

HEPA efficiency |

H13 / H14 /U15 |

|

|

Operating temperature |

10~40℃ |

|

|

Structure type |

Split type |

|

|

Installation mode |

Horizontal / Vertical |

|

HEPA filter parameters

|

HEPA grade |

H13 |

H14 |

U15 |

|

HEPA eff. |

99.99%@0.3um |

99.995%@0.3um |

99.9995%@0.3um |

|

Material |

Glass fibre |

||

|

Frame material |

Aluminium alloy |

||

|

Net cover |

High quality steel baking paint (double-sided) |

||

|

Gasket |

High density synthetic rubber |

||

6.FFU parameters(3 speed type )

|

Model |

3 speed type FFU |

||||||

|

FFU dimension (mm) |

600X400 |

700X400 |

575X575 |

1175X575 |

1350X400 |

1470X400 |

Other |

|

FFU material |

Powder coated |

||||||

|

Fan |

AC |

||||||

|

Input |

220-230ACV/50HZ/1P |

||||||

|

Speed (m/s) |

0.45-1.0m/s Adjustable |

||||||

|

Control type |

Manual / RS485 |

||||||

|

HEPA Height (mm) |

50 / 70 / 90 Optional |

||||||

|

HEPA filter material |

Glass fibre |

||||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||||

|

Operating temperature |

10~40℃ |

||||||

|

Structure type |

Split type / Integrated |

||||||

|

Installation mode |

Horizontal / Vertical |

||||||

7.FFU parameters(3 speed room side replacement type ):

|

Model |

3 speed room side replacement typeFFU |

||||||

|

FFU dimension (mm) |

600X400 |

700X400 |

575X575 |

1175X575 |

1350X400 |

1470X400 |

Other(其他) |

|

FFU material |

Powder coated |

||||||

|

Fan |

AC |

||||||

|

Input |

220-230ACV/50HZ/1P |

||||||

|

Speed (m/s) |

0.45-1.0m/s Adjustable |

||||||

|

Control type |

Manual / RS485 |

||||||

|

HEPA Height (mm) |

50 / 70 / 90 Optional |

||||||

|

HEPA filter material |

Glass fibre |

||||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||||

|

Operating temperature |

10~40℃ |

||||||

|

Structure type |

Integrated |

||||||

|

Installation mode |

Horizontal / Vertical |

||||||

8.FFU parameters(EC energy saving type EC节能型):

|

Model |

EC energy saving type FFU |

||||||

|

FFU dimension (mm) |

600X400 |

700X400 |

575X575 |

1175X575 |

875X575 |

1010X610 |

Other(其他) |

|

FFU material |

Powder coated |

||||||

|

Fan |

EC |

||||||

|

Input |

220-230ACV/50HZ/1P |

||||||

|

Speed (m/s) |

0.45-1.0m/s Adjustable |

||||||

|

Control type |

RS485 |

||||||

|

HEPA Height (mm) |

50 / 70 / 90 Optional |

||||||

|

HEPA filter material |

Glass fibre |

||||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||||

|

Operating temperature |

10~40℃ |

||||||

|

Structure type |

Integrated |

||||||

|

Installation mode |

Horizontal / Vertical |

||||||